Descripción

ENVIAR EMAIL

-

Thomas Edelmann

For the optimum maintenance of disc cutters

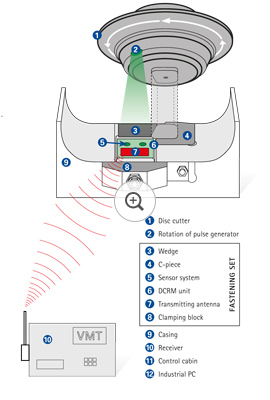

________________ By localizing damaged or blocked disc cutters, the Herrenknecht system optimizes the maintenance intervals on the . Frequent standstills due to manual inspections of the disc cutters are reduced to a minimum – which makes more efficient and avoids secondary damage to the adjacent disc cutters or to the steel construction of the cutterhead.

Detecting wear on and buckets is already a well-established practice on tunnel boring machines at Herrenknecht AG. Expanding our wear management to disc cutters as a next step makes sense technologically.

- online rotation monitoring for every single cutter disc

- area of application: hard rock (open mode)

- cutter size: 17 inch or 19 inch

- flexible autonomous monitoring system (retrofittable and reusable)

- measurement and data evaluation continuously during tunnelling

- data display in the control cabin

Más información sobre este producto consulte en: https://www.herrenknecht.com/en/innovation/research-development/machines-components/dcrm.html