Descripción

ENVIAR EMAIL

- Purge columns for polyolefins

- Conditioning of food products (e.g., sugar, wheat)

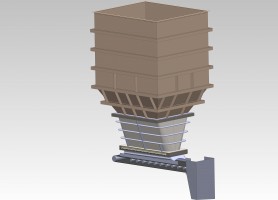

- Hopper dryers for reducing moisture of biomass or plastics

- Contact bed reactors (e.g., catalyst regeneration, reducing operations for DRI)

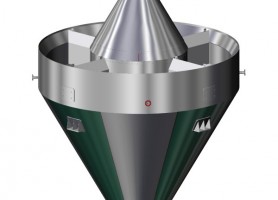

- General configuration that meets your needs (e.g., throughput, spatial constraints)

- Critical bulk material flow properties that help specify vessel design parameters

- Internal surfaces required to provide discharge

- Specialized internals required for anti-channeling gas injection (), control of residence time, or reduction of segregation during filling

- built at European petrochemical complex

- Retrofit of polypropylene in Middle East with J-Purge™ custom insert kit assembled entirely through small man-way access door

- Gravity flow contact bed dryer for reducing moisture to half original value

- Design of new high density polyethylene for removing hydrocarbons

- Design of sugar conditioning vessel to ensure drying does not cause

Más información sobre este producto consulte en: http://jenike.com/engineering/processing-vessels/